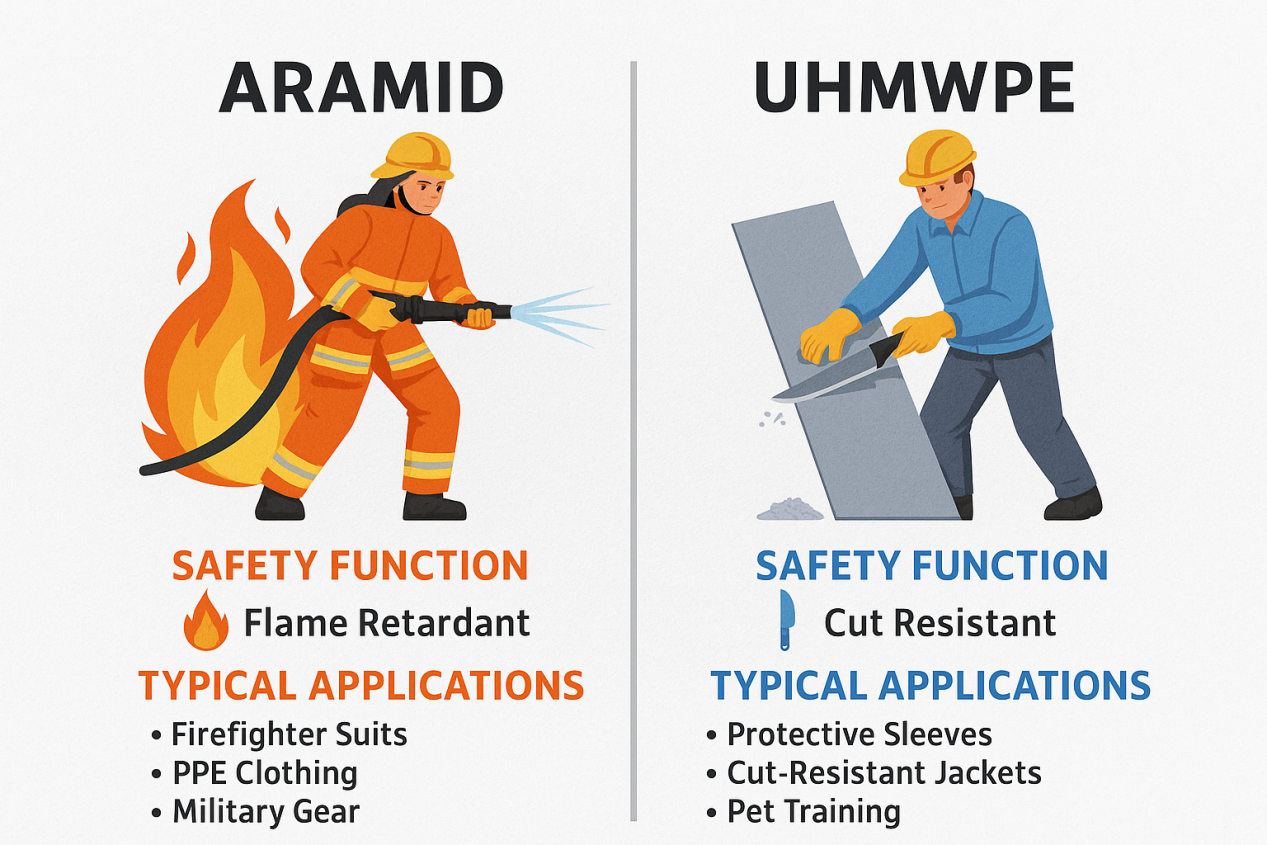

בסביבות מסוכנות, בחירת הבד הנכון יכולה להוות את ההפרש בין פציעה להגנה. שני חומרים שולטים בעולם הבדים לביצועים: ארמיד ו UHMWPE (פוליאתילן עם משקל מולקולרי אולטרא-גבוה) . למרות ששניהם מציעים חוזק יוצא דופן, הם משרתים פונקציות שונות מאוד —במיוחד כאשר дело מגיע ל עמידות בפני להט, קשייה על פני השטח , ו ביצועים תרמיים .

🔥 ארמיד: כיבוי אש בתכונתו

בניגוד לחומרים מוקשהטים, סיבי הארמיד (כגון Kevlar® ו-ארמיד פרה) הם כיבוי אש באופן טבעי. 실 הארמיד הכיבוי אש שלנו והסיל הכבוי אש מסוג ארמיד יכולים לעמוד בטמפרטורות גבוהות מבלי להנתך, להזיע או להתignite—מה שהופך אותם לאידיאלי עבור בגדים של כובסי אש, בגדים צבאיים ואישורי עבודה מגינים.

יתרה מכך, הבד הארמיד עמיד בפני קשייה שלנו מציע עמידות מעולה בפני שטח, מתאים לשרשורים שנחשפים לחיכוך תדיר ולמאמצים מכניים.

בדי קבר היגדירים משמשים במדים בהם יש צורך גם בשמירה תרמית וגם בחוזק - כפפות, כובעים Защитные рукавונים וחגורות יציאה.

🔥 UHMWPE: עמידות בגזירה קלה, עם פשרות מסוימות

UHMWPE מוערך בשל יחס החוזק-למשקל הנוסף שלו, מה שהופך אותו לבחירה המועדפת להגנה קלה נגד גזירה. בדינו האנטי-גזירה ובדיו העמידים בפני גזירה משמשים לרוב ב:

Рукавונים Защитные и כפפות הגנה

חוצות וג'ינסים עמידים בפני גזירה

מוצרי אימוץ לכלבים וציוד ביטחון ביתי

עם זאת, UHMWPE אינו עמיד באש באופן טבעי, והוא עשוי להתעוות בטמפרטורות גבוהות. לכן הוא מתאים יותר להגנה מפני גזירה, לא בפני חשיפה תרמית.

עבור יישומים בהם יעילות כלכלית ונוחות הן המפתח, אנו מספקים גם חוט מעכב בעירה מודאקרילי, אידיאלי לבגדי עבודה, שכבות בסיס ובטנות מעכבות בעירה הדורשות רכות ועמידה בתקני הבטיחות EN/ISO.

✅ למה לבחור בנו?

עכבת להבה: חוטי ארמיד ומודאקריל מוסמכים

עמידה בפני חיתוך: טקסטיל UHMWPE עם דירוג ANSI/EN388

עמידה בפני שחיקה: ביצועים עמידים ואיכותיים לאורך זמן

אפשרויות מותאמות אישית: ספירת חוט, דניר, צביעה, שילוי זמין

MOQ נמוך + דגימות מהירות

📩 צרו קשר

בין אם אתם מחפשים ארמיד לביטחון תרמי, או UHMWPE להגנה מפני חיתוך – אנו מספקים חומרים מוסמכים ובדוקי ביצועים המותאמים למדורים מקצועיים, צבא, ציוד לכלבים ולבוש טכנולוגי.

👉 בקרו אותנו בכתובת www.stmingdaaramid.com

📧 צרו איתנו קשר בכדי לבקש דגם חינם או גיליון מידע.