Introduction

Ultra-High Molecular Weight Polyethylene (UHMWPE) represents one of the most significant advancements in engineering plastics and high-performance fibers. This remarkable material combines exceptional strength with lightweight properties, making it invaluable across numerous industries from defense to healthcare. As global demand for high-performance materials continues to grow, understanding UHMWPE's unique properties, applications, and identification methods becomes increasingly important for engineers, procurement specialists, and materials scientists.

What is Ultra-High Molecular Weight Polyethylene?

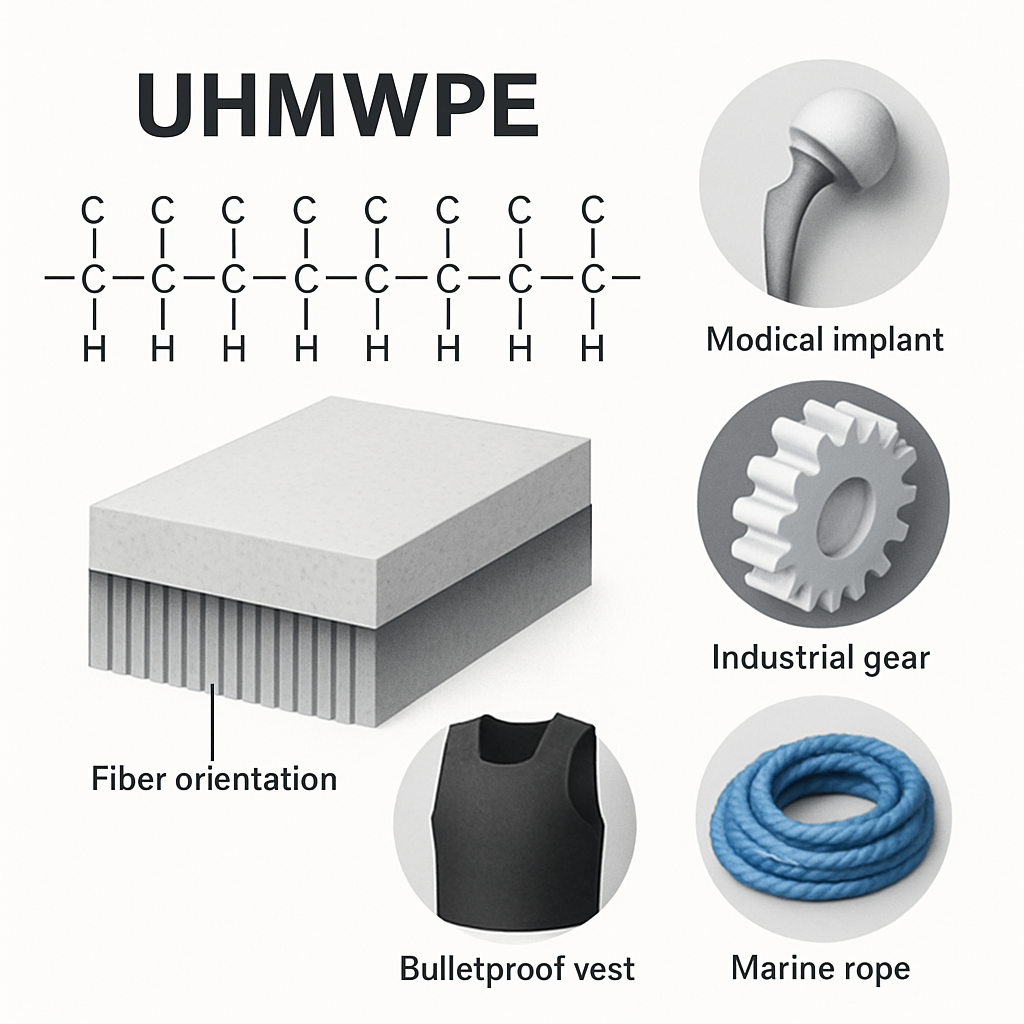

Ultra-High Molecular Weight Polyethylene (UHMWPE) is defined as a linear polyethylene with a molecular weight exceeding 1.5 million and no branched chains. Its molecular formula is —(—CH2-CH2—)—n—, with a density ranging from 0.920 to 0.964g/cm³. The material exhibits a heat deflection temperature (at 0.46MPa) of 85°C and a melting point between 130-136°C.

As a thermoplastic engineering plastic with a linear structure, UHMWPE offers an exceptional combination of properties that distinguish it from conventional polymers and even other high-performance materials. Its unique molecular structure, characterized by extremely long chains, contributes to its outstanding mechanical properties and chemical resistance.

Historical Development

The development trajectory of UHMWPE illustrates its growing importance in materials science:

● Pre-1980s: Global annual growth rate averaged 8.5%

● Post-1980s: Growth accelerated to 15-20% annually

● China's Growth: Exceeded 30% annual growth rate

In quantitative terms, global consumption grew from approximately 12,000-12,500 tons in 1978 to around 50,000 tons by 1990, with the United States accounting for 70% of demand. The period from 2007-2009 marked a significant shift as China emerged as a global manufacturing center for engineering plastics, further accelerating UHMWPE industry development.

The technological evolution of UHMWPE spans nearly a century:

- 1930s: Initial theoretical foundations for ultra-high molecular weight polyethylene fibers were established

- 1964: China successfully developed and implemented industrial production

- 1970s: University of Leeds researchers Capaccio and Ward developed high molecular weight polyethylene fibers (100,000 MW)

- 1975: Dutch researchers invented the gel spinning method using decahydronaphthalene as a solvent

- 1979: Patent application for gel spinning method

- 1983: Japan developed production techniques using gel extrusion and super-stretching with paraffin as solvent

- 2001: In China, UHMWPE pipes were designated as a priority in the National Science and Technology Achievement Promotion Plan

This continuous development has established UHMWPE as a critical material in advanced applications across multiple sectors.

Identifying Genuine UHMWPE

As with many high-performance materials, the market includes varying qualities of UHMWPE. Authentic ultra-high molecular weight polyethylene can be identified through several reliable methods:

Weight Method

Products manufactured from pure UHMWPE have a specific gravity between 0.93-0.95, resulting in a density low enough to float on water. Non-genuine materials typically sink.

Visual Inspection

Genuine UHMWPE exhibits:

● Flat, uniform, and smooth surface appearance

● Cross-sections with highly uniform density

● Consistent coloration throughout the material

Edge Testing

When examining the edges of UHMWPE products:

● Pure UHMWPE has rounded, uniform, and smooth edges

● Non-genuine materials show cracks at the edges

● When heated and folded, inferior materials will shed particles, while genuine UHMWPE maintains its integrity

These identification methods are essential for quality assurance in critical applications where material performance directly impacts safety and functionality.

Key Properties and Characteristics

UHMWPE fiber represents the third generation of special fibers in modern materials science. Its exceptional properties include:

● Superior Strength: Reaching up to 30.8cN/dtex, it possesses the highest specific strength among chemical fibers

● Wear Resistance: Exceptional resistance to abrasion and wear, making it ideal for high-friction applications

● Impact Resistance: Outstanding ability to absorb energy from impacts

● Corrosion Resistance: Highly resistant to chemicals, acids, and bases

● Light Resistance: Excellent stability when exposed to UV radiation

● Self-Lubrication: Inherent lubricity that reduces friction without additional lubricants

● Biocompatibility: Compatible with human tissue, making it suitable for medical applications

This combination of properties has positioned UHMWPE as a critical material in high-performance applications, from offshore mooring ropes to lightweight composite materials. Its role in modern warfare, aviation, aerospace, and maritime defense equipment continues to expand as new applications are developed.

Applications Across Industries

Defense and Military

The exceptional impact resistance and specific energy absorption of UHMWPE make it invaluable in defense applications:

● Protective clothing and body armor

● Ballistic helmets

● Armor protection plates for helicopters, tanks, and naval vessels

● Radar protective covers

● Missile covers

● Bulletproof and stab-resistant vests

● Tactical shields

● Parachutes for personnel and equipment

Aerospace Engineering

The lightweight, high-strength properties of UHMWPE are particularly advantageous in aerospace:

● Aircraft wing tip structures

● Spacecraft structural components

● Float plane elements

● Deceleration parachutes for spacecraft landing

● Suspension ropes for heavy equipment, replacing traditional steel cables

● Composite reinforcement in critical structures

Marine and Offshore

In marine applications, UHMWPE offers significant advantages:

● Ropes and cables with breaking lengths 8 times that of steel ropes and twice that of aramid

● Ship sails with exceptional durability

● Fishing equipment resistant to saltwater corrosion

● Mooring ropes for supertankers and oil platforms

● Anchor lines for lighthouses and offshore structures

These applications solve critical problems associated with steel cables (rusting) and synthetic ropes (hydrolysis, UV degradation, and strength reduction), significantly reducing replacement frequency and improving safety.

Industrial Manufacturing

The industrial applications of UHMWPE are extensive:

● Pressure vessels for chemical processing

● Conveyor belts in abrasive environments

● Filtration materials for aggressive media

● Automotive buffer plates

● Construction materials for wall structures and partition systems

● Cement reinforcement to improve toughness and impact resistance

● Mechanical components including:

● Gears

● Cams

● Impellers

● Rollers and pulleys

● Bearings

● Bushings and shaft sleeves

● Gaskets and seals

● Elastic couplings

● Specialized fasteners

Sports Equipment

In sporting goods, UHMWPE has revolutionized performance:

● Safety helmets with superior impact protection

● High-performance skis and snowboards

● Sailboards with exceptional durability

● Fishing rods combining strength and flexibility

● Tennis and badminton rackets

● Bicycle components requiring high strength-to-weight ratios

● Gliders and ultralight aircraft parts

● Climbing ropes and equipment

In each case, UHMWPE offers performance advantages over traditional materials, enhancing both safety and performance.

Medical Applications

The biocompatibility and durability of UHMWPE make it particularly valuable in medical applications:

● Dental tray materials

● Medical implants, particularly orthopedic

● Surgical sutures

● Prosthetic components

● Medical gloves

● Specialized medical equipment

Its biological compatibility, durability, and stability prevent allergic reactions and support long-term clinical applications.

Future Trends and Innovations

As research continues, several promising directions for UHMWPE development are emerging:

1.Nanocomposite Formulations: Incorporating nanomaterials to further enhance specific properties

2.Surface Modification Techniques: Improving adhesion properties for composite applications

3.Processing Innovations: New methods to overcome traditional processing challenges

4.Recycling Technologies: Sustainable approaches to UHMWPE lifecycle management

5.Hybrid Materials: Combinations with other high-performance materials for specialized applications

Conclusion

Ultra-High Molecular Weight Polyethylene represents a remarkable achievement in materials science, offering an exceptional combination of properties that continue to enable innovations across multiple industries. From life-saving defense applications to medical implants improving quality of life, UHMWPE demonstrates how advanced materials can transform our technological capabilities.

As research continues and manufacturing techniques evolve, we can expect UHMWPE to play an increasingly important role in addressing complex engineering challenges and enabling next-generation products across the industrial spectrum.

For more information about our UHMWPE products and technical specifications, please contact our materials engineering team or explore our product catalog.