Aramid nanofiber (ANF) membranes possess broad application prospects in numerous fields due to their unique properties. However, how to further enhance their mechanical strength while reducing thermal conductivity has become a current research focus and major challenge in this field. Traditional methods have obvious limitations in constructing strong hydrogen bond networks to improve the performance of ANF membranes; therefore, there is an urgent need for new strategies to optimize the structure and performance of ANF membranes.

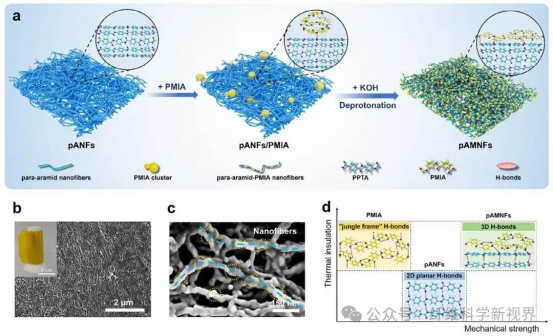

It demonstrates the preparation process of pAMNFs (the deprotonation process of pANFs → pANFs/PMIA → pAMNFs), presents the comparison between the two-dimensional planar hydrogen bond structure of pANFs and the three-dimensional hydrogen bond structure of pAMNFs, labels the "Nanofibers 'jungle frame'", and associates it with the relevant diagram of Mechanical Strength.

l Core Strategy: Introduce a "double deprotonation" strategy to treat aramid nanofibers (ANFs) for constructing a three-dimensional hydrogen bond network.

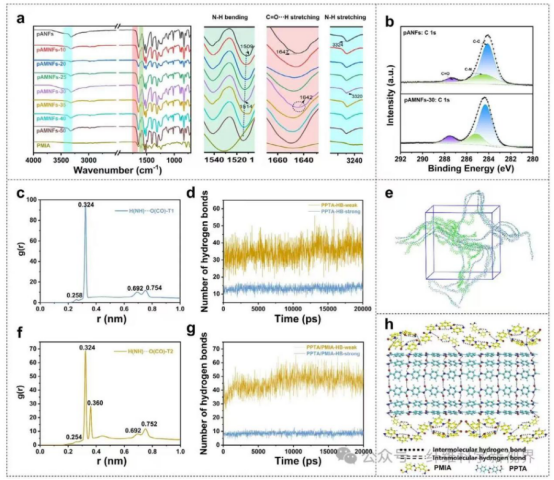

Fourier Transform Infrared Spectroscopy (FT-IR) and X-ray Photoelectron Spectroscopy (XPS) are employed to analyze the surface chemical structure of fibers and verify changes in polar functional groups.

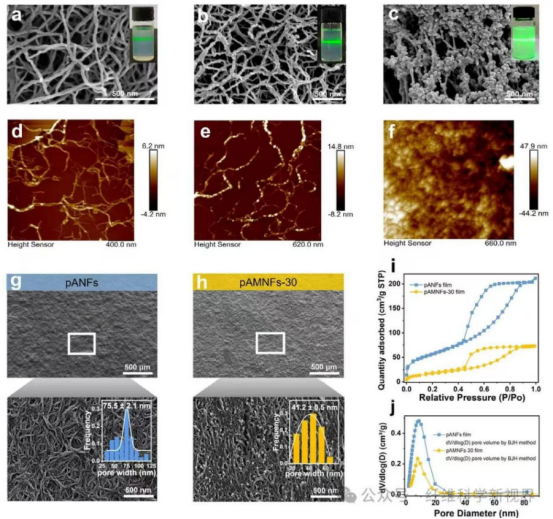

Atomic Force Microscopy (AFM) and Scanning Electron Microscopy (SEM) are used to observe the microtopography of fibers and membranes, so as to understand the structure optimization.

l Performance Tests:

A universal testing machine is used to test mechanical performance indicators of membranes, such as tensile strength and elastic modulus. A laser thermal conductivity meter is applied to measure the thermal conductivity of membranes and evaluate their thermal insulation performance.

It includes Atomic Force Microscopy (AFM) height sensor images (with height data at different positions labeled: 6.2 nm, 14.8 nm, 47.9 nm, etc.), Scanning Electron Microscopy (SEM) images (comparison of micro morphologies between pANFs and pAMNFs-30 at the 500 nm scale), relative pressure-pore size distribution curves, and Barrett-Joyner-Halenda (BJH) method-based pore volume-pore size distribution curves, demonstrating the differences in the microstructure of the thin films before and after treatment.

A three-dimensional hydrogen bond network was successfully constructed. The double deprotonation effect generated more polar groups on the surface of aramid nanofibers (ANFs), creating favorable conditions for the formation of a three-dimensional hydrogen bond network between fibers. The test results of Fourier Transform Infrared Spectroscopy (FT-IR) and X-ray Photoelectron Spectroscopy (XPS) showed that the number of polar functional groups on the fiber surface increased significantly after treatment, providing more active sites for hydrogen bond formation and ultimately leading to the successful construction of a stable three-dimensional hydrogen bond network.

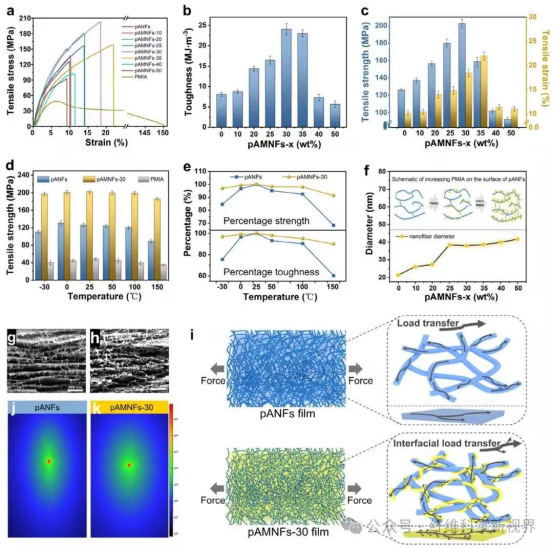

It presents multiple sets of mechanical property data charts: tensile strain-stress curves (comparing pANFs with pAMNFs of different PMIA contents), a graph of the relationship between PMIA content and properties in pAMNFs, curves of the effect of temperature on strength/toughness, and a schematic diagram of interfacial load transfer between pANFs and pAMNFs-30, intuitively demonstrating the enhancement effect of mechanical properties.

Mechanical Properties Are Significantly Enhanced.

Benefiting from the supporting effect of the three-dimensional hydrogen bond network, the mechanical properties of the aramid nanofiber (ANF) membrane have been greatly improved. Experimental data show that compared with the untreated aramid nanofiber membrane, the tensile strength of the composite membrane (pAMNFs) after double deprotonation treatment can be increased several times, and the elastic modulus is also significantly enhanced, endowing it with a stronger competitive advantage in high-strength material application scenarios.

It includes Fourier Transform Infrared (FT-IR) spectra (with positions of characteristic peaks such as N-H bending, C=O⋅⋅⋅H stretching, and N-H stretching labeled), X-ray Photoelectron Spectroscopy (XPS) C 1s orbital binding energy spectra, hydrogen bond distance-distribution function curves, and hydrogen bond lifetime vs. time curves, verifying the changes in chemical structure and the enhancement of hydrogen bond interaction after double deprotonation.

Thermal Conductivity Is Significantly Reduced.

The presence of the three-dimensional hydrogen bond network exerts an obvious hindering effect on heat transfer, leading to a significant reduction in the thermal conductivity of the composite membrane (pAMNFs). Test results show that the thermal conductivity of this membrane can be reduced to an extremely low level, demonstrating excellent thermal insulation performance and exhibiting good application potential in the field of thermal insulation materials.

Microstructure Optimization

Images captured by Scanning Electron Microscopy (SEM) and Atomic Force Microscopy (AFM) show that after double deprotonation treatment, the aramid nanofibers (ANFs) in the membrane are arranged more regularly, and the bonding between fibers is tighter, forming a uniform and dense microstructure. This structural optimization is one of the important reasons for the improvement of the film’s mechanical strength and the reduction of its thermal conductivity.

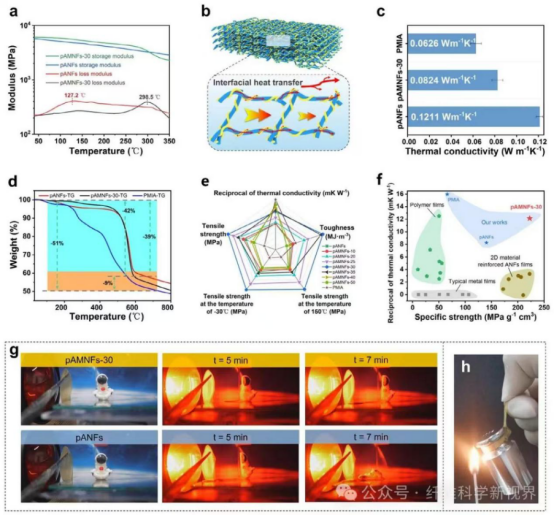

It presents storage modulus/loss modulus-temperature curves, thermal conductivity comparison charts (the thermal conductivity of pAMNFs-30 is as low as 0.0626 W·m⁻¹·K⁻¹), thermogravimetric analysis (TG) curves, specific strength vs. toughness comparison charts of different materials, and performance change comparisons between pAMNFs-30 and pANFs over different time periods, comprehensively demonstrating the mechanical and thermal advantages of the thin film.

The "double deprotonation" strategy proposed in this study successfully constructs a three-dimensional hydrogen bond network in aramid nanofiber (ANF) membranes. This not only effectively improves the mechanical strength of the membranes but also significantly reduces their thermal conductivity. The method features simple operation and remarkable effects, providing a new approach for the performance optimization of aramid nanofiber materials. In the future, this high-performance composite membrane (pAMNFs) is expected to be widely applied in multiple fields such as aerospace, heat dissipation of electronic devices, and high-performance composite materials, thereby promoting the technological development of related industries.