In the current global textile industry where "safety, environmental protection, and sustainability" are increasingly valued, material innovation has become the core driving force to break through industrial bottlenecks. As a leading enterprise deeply engaged in the fiber field, Kaneka Corporation has recently launched the next-generation Protex-F and Protex-H fibers. With "antimony-free" as the core highlight, these fibers integrate high flame retardancy and environmental protection properties. They not only meet strict international certification standards but also redefine the technical boundaries of functional fibers, bringing new possibilities to downstream application scenarios.

I.Core Breakthrough: "Antimony-Free" Innovation, Initiating Dual-Dimension Upgrade of Safety and Environmental Protection

Traditional flame-retardant fibers often rely on antimony to achieve flame-retardant effects. However, the presence of antimony not only poses potential health risks but also runs counter to the global environmental protection trend. The primary innovation of Protex-F and Protex-H is the realization of an "Antimony free" formula design. This breakthrough directly reduces the environmental burden of the material throughout its entire life cycle (production, use, and disposal) and eliminates safety hazards in downstream applications (such as infant textiles and intimate clothing), truly achieving "lower risk and environment friendly" .

What is more noteworthy is that both products have obtained the OEKO-TEX STANDARD 100 Class I certification . As one of the most authoritative ecological certifications in the textile industry, Class I is the highest-level standard for infant products. This means Protex-F and Protex-H have reached extremely strict levels in the control of harmful substances and can be directly used in scenarios with high safety requirements, such as maternal and infant textiles and medical protective fabrics.

II. Positioning as Next-Generation Products: High Flame Retardancy + Blending Compatibility, Breaking Technical Limitations

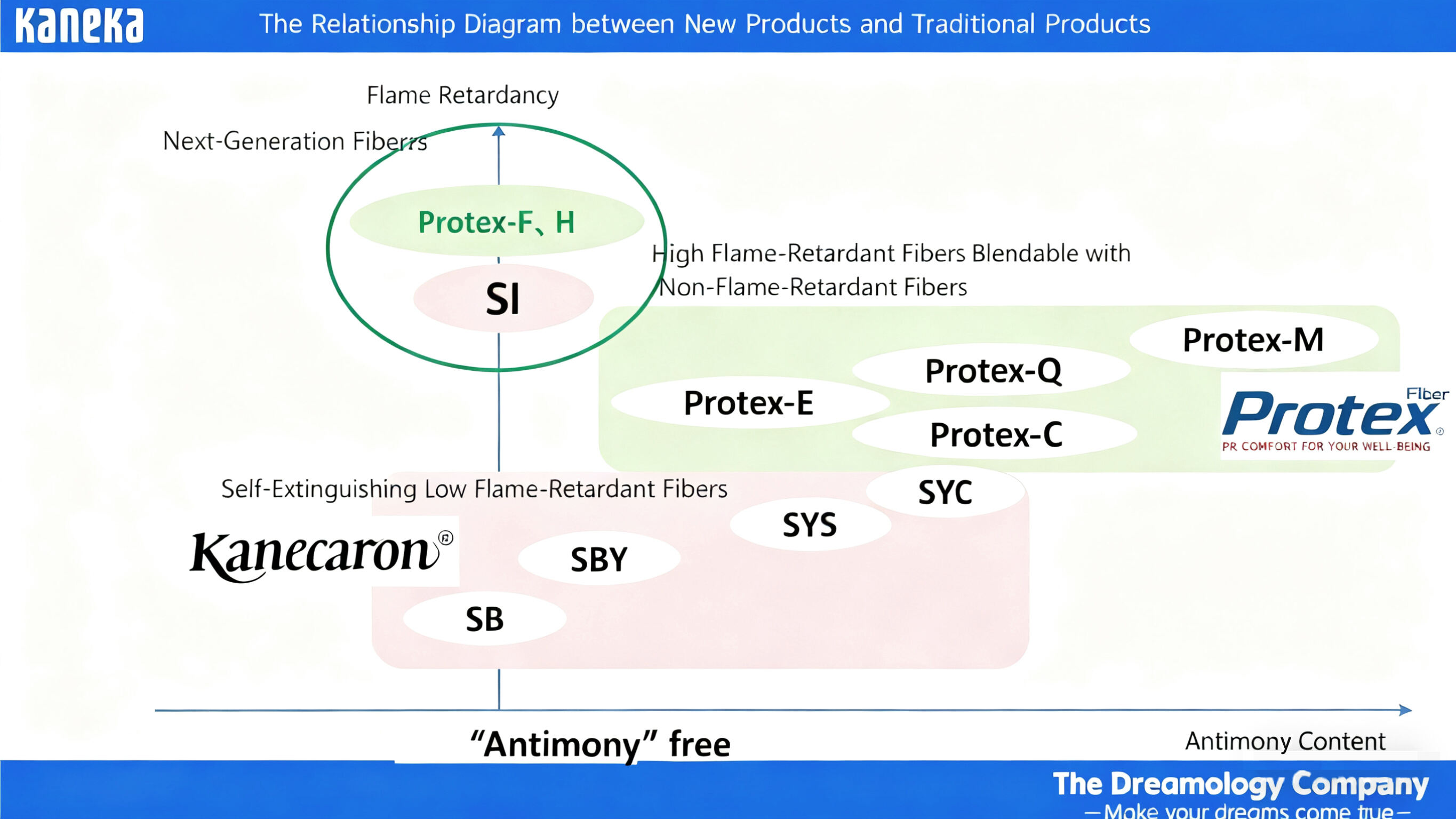

In the product matrix, Protex-F and Protex-H are not simple iterations but represent Kaneka's new layout for "next-generation flame-retardant fibers". It can be clearly seen from the Relationship Diagram between New Products and Traditional Products (it is recommended to attach the diagram of the relationship between new and traditional products from the PDF here) that both belong to the category of "Next-Generation Fibers", with the core advantage of "high flame retardancy + blendable with non-flame-retardant fibers" . This feature solves the pain point of traditional high flame-retardant fibers that "can only be used alone and are difficult to adapt to diversified fabrics".

Compared with traditional products (such as Protex-M, Protex-C, and Protex-E), Protex-F and Protex-H do not rely on a single flame-retardant fiber formula. They can be flexibly blended with non-flame-retardant fibers such as cotton and polyester, which not only retains high flame-retardant effects but also takes into account the practical properties of fabrics such as hand feel and air permeability. For example, in scenarios such as home textiles and automotive interiors, the blending solution can significantly reduce fabric costs while meeting industry flame-retardant standards, providing downstream enterprises with more flexible design space.

III. High-Performance: Data Witnesses Product Strength, with Full Attention to Practical Value

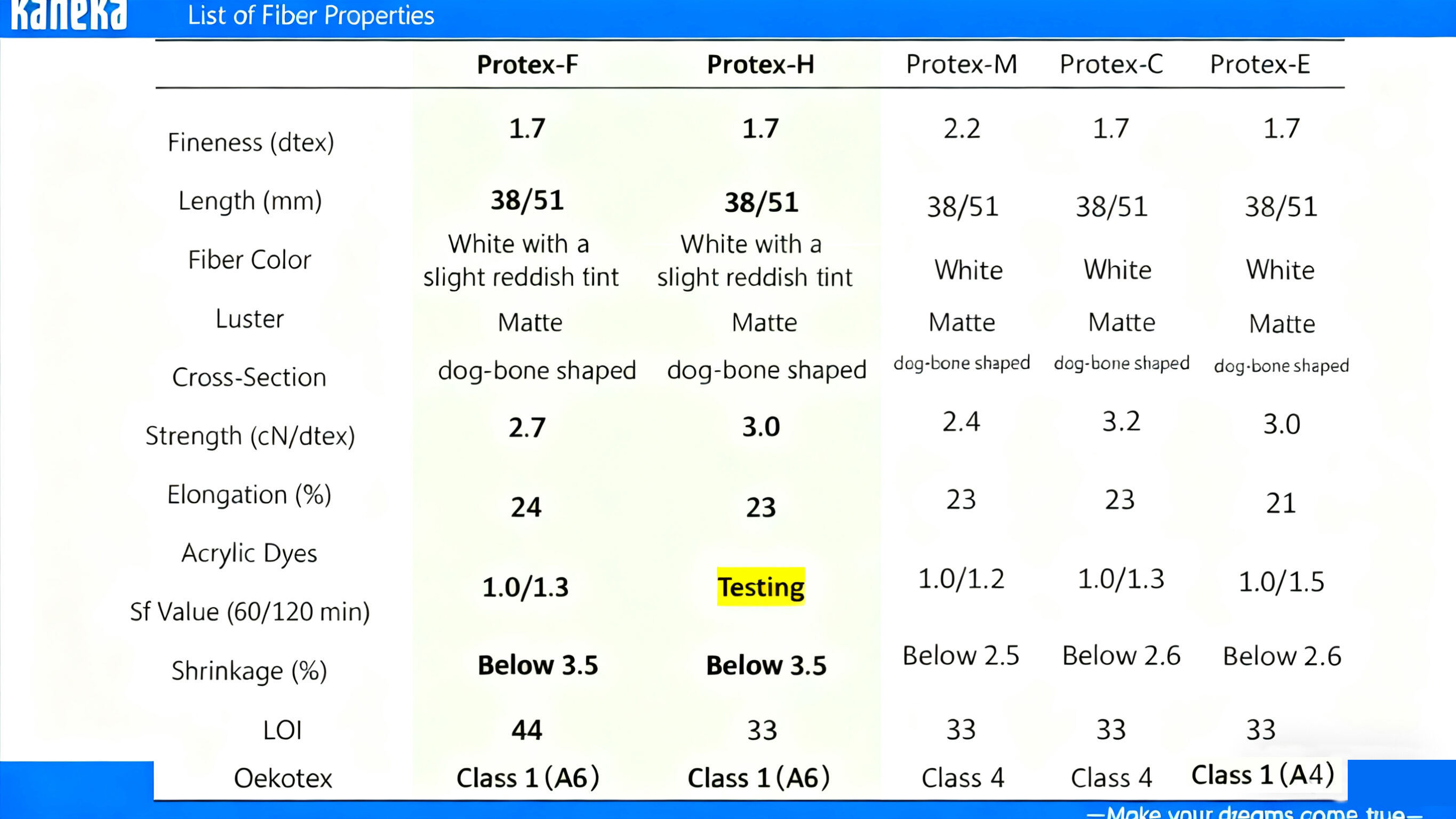

The performance parameters of the two products show "balanced and excellent" characteristics:

● Unified and widely adaptable basic properties: Both have a fineness of 1.7 dtex, with lengths covering two mainstream specifications of 38mm/51mm. Their cross-sections are dog-bone shaped (conducive to dyeing and air permeability), and both have a matte texture and white color with a slight reddish tint . This design not only avoids the "industrial feel" of traditional flame-retardant fibers but also can adapt to the dyeing needs of most fabrics, reducing subsequent processing procedures.

● Stable mechanical properties: The strength of Protex-H reaches 3.0 cN/dtex, and that of Protex-F is 2.7 cN/dtex, both higher than those of traditional products such as Protex-M (2.4 cN/dtex) . This means the fabrics are more wear-resistant, less likely to break; the elongation is controlled at 23%-24%, taking into account elasticity and shape retention, making them suitable for scenarios requiring multiple washes.

● Excellent flame retardancy and stability: In terms of the key indicator Limited Oxygen Index (LOI), Protex-F reaches 44 and Protex-H reaches 38, far higher than ordinary fibers (LOI is about 20) . Even when blended with cotton, they can still maintain high LOI values of 50 (Protex-F + cotton) and 40 (Protex-H + cotton), with no compromise on flame-retardant effects . At the same time, the shrinkage rate of both is below 3.5%, solving the industry problem of "easy deformation" of flame-retardant fabrics .

IV. Sustainable Layout: Chemical Recycling + Certification Advancement, Contributing to Circular Economy

In addition to the environmental protection properties of the products themselves, Kaneka's layout in sustainable development is more forward-looking. Protex-F will take the lead in launching the chemical recycling model, and the quality of its recycled products can be equivalent to that of virgin fibers . This means that waste Protex-F fabrics do not need to rely on the "downcycling" of physical recycling but can be converted back into high-quality fibers through chemical processes, realizing a closed-loop cycle of resources.

At the same time, the ISCC Plus certification for the Protex series is in progress . As a globally recognized certification standard for sustainable supply chains, ISCC Plus covers three dimensions: environment, society, and economy. The advancement of this certification will further prove the sustainability of Protex-F/H in the entire industrial chain, providing more reliable options for brand customers who focus on ESG (Environmental, Social, and Governance).

Conclusion: From Material Innovation to Industrial Empowerment, the Industrial Value of Protex-F/H

The launch of Kaneka Protex-F and Protex-H is not only a product upgrade but also a precise response to the "safety, environmental protection, and sustainability" needs of the textile industry. The "antimony-free" formula eliminates health and environmental hazards, the high flame-retardant blending capability breaks application limitations, and coupled with the sustainable recycling layout, these two fibers are becoming a key force driving the upgrading of textile materials in fields such as home furnishing, medical care, and automobiles.

In the future, with the completion of ISCC Plus certification and the popularization of chemical recycling technology, Protex-F/H is expected to further lead the "greening" trend of functional fibers