In the ever-evolving world of materials science, Mdacrylic fiber has emerged as a remarkable synthetic material with a wide range of applications. This article delves into the properties, production, and diverse uses of Mdacrylic fiber, shedding light on its significance in various industries.

What is Mdacrylic Fiber?

Mdacrylic fiber, also known as modified acrylic fiber, is a synthetic polymer-based fiber. It is primarily composed of acrylonitrile units, but with the addition of other monomers to modify its properties. The Federal Trade Commission defines Mdacrylic fibers as manufactured fibers in which the fiber-forming substance is any long-chain synthetic polymer composed of less than 85%, but at least 35% by weight of acrylonitrile units (except when the polymer qualifies as rubber). This unique composition gives Mdacrylic fiber its distinct characteristics.

Properties of Mdacrylic Fiber

● Flame Retardancy

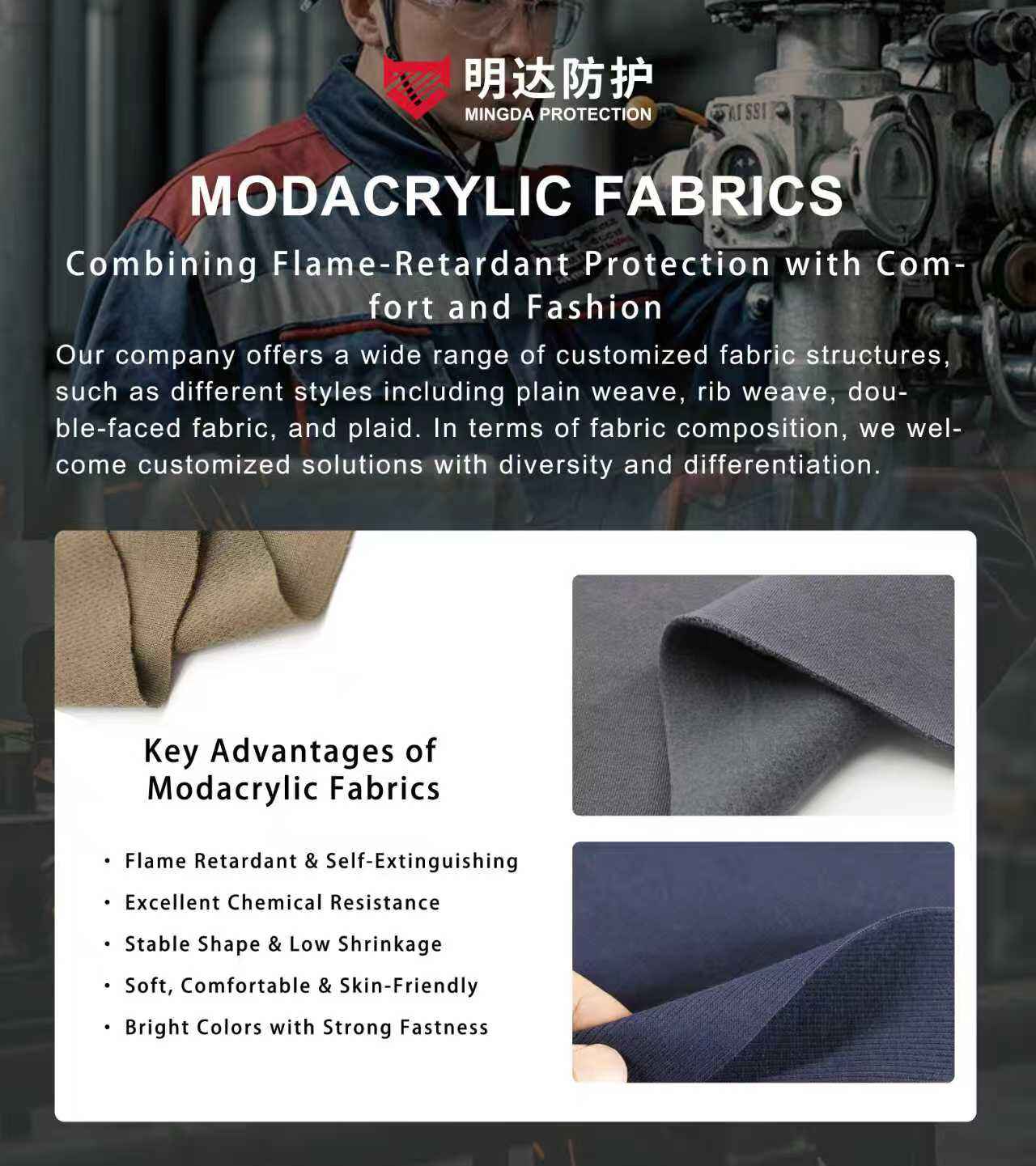

One of the most notable properties of Mdacrylic fiber is its excellent flame retardancy. It is difficult to ignite and will self-extinguish when the source of ignition is removed. This makes it an ideal choice for applications where fire safety is crucial, such as in protective clothing for firefighters, industrial workers, and in home furnishings like flame-resistant draperies and carpets. [Insert an image here of a Mdacrylic fiber sample being exposed to a flame, showing its self-extinguishing property. The image should be a high-resolution photo, with the fiber in a clear view and the flame in the background, highlighting the lack of significant combustion.]

● Softness and Resilience

Mdacrylic fiber is soft to the touch, providing a comfortable feel in textile applications. It is also highly resilient, meaning it can easily return to its original shape after being stretched or deformed. This property contributes to its use in products that require shape retention, such as upholstery and certain types of apparel.

● Dyeability

The fiber has good dyeability, allowing it to be colored in a wide range of bright and vibrant shades. This makes it aesthetically appealing for use in fashion, home decor, and other applications where visual appeal is important. [Include an image of a variety of Mdacrylic fiber products in different colors, such as dyed fabrics, to showcase its dyeability. The image should display the rich and vivid colors clearly.]

● Chemical and Solvent Resistance

Mdacrylic fiber exhibits outstanding resistance to chemicals and solvents. It is not easily attacked by moths or mildew, and it is nonallergenic. These properties make it suitable for use in harsh environments and in applications where durability and resistance to degradation are essential.

● Dimensional Stability

It has high dimensional stability, which means it maintains its shape well over time, even under varying conditions of temperature and humidity. This property is crucial for applications where consistent sizing and shape are required, such as in industrial fabrics and certain types of filters.

Production of Mdacrylic Fiber

The production of Mdacrylic fiber involves several steps. First, the components, including acrylonitrile and other monomers, are polymerized to form a copolymer. This copolymer is then dissolved in a suitable solvent, such as acetone. The resulting solution is pumped into a column of warm air in a process known as dry spinning. As the solution is exposed to the warm air, the solvent evaporates, and the copolymer solidifies into fibers. During this process, the fibers can be stretched while hot to achieve the desired properties, such as increased strength and specific shrinkage characteristics. The fibers are produced in various forms, including staple fiber (short lengths) and filament (continuous long lengths), and can have different lengths, crimp levels, and deniers (a measure of fiber fineness). [Insert a diagram here showing the production process of Mdacrylic fiber. The diagram should be a clear, labeled flowchart, starting from the raw materials, showing the polymerization process, the dissolution in acetone, the dry spinning in the warm air column, and the final production of different fiber forms.]

Applications of Mdacrylic Fiber

● Protective Apparel

Mdacrylic fiber's flame retardant and other desirable properties make it a popular choice for protective clothing. It is used in the manufacturing of fire-resistant uniforms for firefighters, ensuring their safety in high-temperature and fire-prone environments. In addition, it is also used in work clothing for industries where there is a risk of exposure to flames, sparks, or chemicals, such as in the oil and gas, welding, and foundry industries. [Show an image of firefighters wearing Mdacrylic fiber-based protective gear. The image should clearly display the gear, with the firefighters in action, highlighting the functionality and importance of the Mdacrylic fiber in their safety.]

● Home Furnishings

In the home furnishings industry, Mdacrylic fiber is used in a variety of products. Its flame retardant property makes it suitable for use in draperies, curtains, and carpets, providing an added layer of safety in the home. It is also used in upholstery due to its softness, resilience, and ability to maintain its shape over time, ensuring long-lasting comfort and aesthetic appeal in furniture. [Include an image of a living room with Mdacrylic fiber-based draperies and upholstered furniture. The image should show the overall aesthetic of the room, with the Mdacrylic fiber products standing out for their quality and appearance.]

● Industrial Applications

Mdacrylic fiber finds extensive use in industrial applications. Its chemical and solvent resistance, along with its dimensional stability, make it suitable for use in industrial fabrics, such as those used in filtration systems. In filtration, the fiber can effectively trap particles while maintaining its integrity in the face of harsh chemicals and varying operating conditions. It is also used in the production of paint rollers, where its absorbent and durable properties are beneficial. [Insert an image of an industrial filtration system with Mdacrylic fiber components. The image should show the system in operation, with the Mdacrylic fiber parts clearly visible, demonstrating its role in the industrial process.]

● Textile and Fashion

In the textile and fashion industry, Mdacrylic fiber is used to create a variety of products. It can be blended with other fibers to enhance the performance and aesthetic of fabrics. For example, it is often used in simulated fur products, where its softness and ability to be processed into different lengths mimic the look and feel of natural fur. It is also used in wigs and hairpieces due to its good dyeability and resemblance to natural hair. [Show an image of a fashion model wearing a garment made from Mdacrylic fiber or a Mdacrylic fiber-based wig. The image should showcase the style and quality of the product, highlighting the fiber's contribution to the fashion item.]

Conclusion

Mdacrylic fiber is a versatile and innovative synthetic material that offers a combination of desirable properties. Its flame retardancy, softness, resilience, dyeability, chemical resistance, and dimensional stability make it suitable for a wide range of applications in various industries. As technology continues to advance, it is likely that Mdacrylic fiber will find even more innovative uses, further enhancing its significance in the world of materials science and manufacturing. Whether in protecting lives in high-risk environments, adding comfort and style to our homes, or contributing to the efficiency of industrial processes, Mdacrylic fiber has proven to be a valuable addition to the materials palette.