Workers in high-risk occupations such as firefighters and race car drivers have an urgent need for underwear that combines flame resistance and comfort. It must not only protect against high-temperature burns but also wick away sweat quickly. However, existing products either use high-cost flame-retardant fibers (e.g., meta-aramid) which are expensive, or adopt a blend of modacrylic and cotton which has poor moisture absorption—making it difficult to achieve both goals.

To address this, the research team developed a new blending scheme consisting of 55% Modacrylic Fiber (MAC), 15% Polyacrylate Fiber (PAC), and 30% Lyocell Fiber (CLY). Tests have confirmed that this scheme balances cost, flame resistance, and comfort, providing a new path for the development of economical flame-resistant underwear.

I. Core Pain Points: Limitations of Traditional Schemes

● Needs in Extreme Environments: Temperatures in fire scenarios can reach 1700°C, so underwear must be flame-resistant to prevent burns. High-intensity work leads to heavy sweating, requiring quick moisture absorption and wicking to avoid stuffiness.

● Shortcomings of Traditional Schemes: High-cost fibers are 3-4 times more expensive than modacrylic, making them difficult to popularize. The 65% modacrylic/35% cotton blend has a long wetting time of 480-960 seconds, resulting in low water absorption efficiency.

II. New Blending Scheme: Fibers and Processes

1、Complementary Advantages of Fibers

MAC: Serves as the flame-retardant core. It carbonizes without melting at high temperatures, with a Limiting Oxygen Index (LOI) of 32.5%. It is also wear-resistant and easy to clean.

PAC: Excels in both flame resistance (LOI 42%) and moisture absorption (moisture regain 15.55%), enhancing the overall moisture absorption capacity of the blend.

CLY: An environmentally friendly regenerated fiber with better moisture absorption (moisture regain 8-14%) than cotton. It has excellent moisture permeability to accelerate sweat evaporation.

2、Key Process Variables

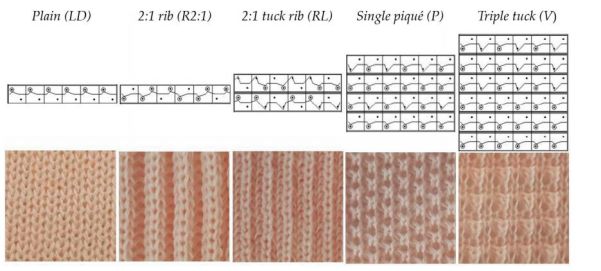

Controlled experiments were conducted by adjusting fiber fineness (1.7dtex/1.0dtex MAC), spinning processes (ring spinning/compact spinning/siro spinning), and knitted fabric structures (5 types including plain weave, 2:1 rib, and pique rib), ensuring the results are applicable to actual production.

III. Performance Verification: Meeting Standards for Both Flame Resistance and Comfort

1、Basic Performance

● Fibers are evenly distributed in the yarn and remain stable below 200°C (MAC resists up to 220°C, CLY up to 250°C), meeting the requirements of high-temperature environments.

● The breaking strength of yarn made from 1.0dtex MAC is 13.7% higher than that of regular yarn. Compact-spun yarn has the least hairiness, preventing pilling.

2. Moisture Absorption and Sweat Wicking

The new blend has a wetting time of only 5-14.6 seconds and a water absorption time of 4.6-21.4 seconds, far superior to traditional blends (480-960 seconds). The triple tuck structure offers the best moisture absorption, while the 2:1 rib structure is relatively slower.

3. Flame Resistance and Safety

Complying with the ISO 15025 standard, all samples have a afterflame time and glowing time of less than 2 seconds, with no melting or dripping. The 2:1 rib structure provides the best flame resistance. PAC and MAC work synergistically to enhance flame resistance, and improved moisture absorption does not compromise safety.

IV. Application Value and Future Optimization

Core Advantages

1、Low Cost: The material cost is only 1/3 to 1/4 of meta-aramid, and no additional chemical flame-retardant treatment is required.

2、Safe and Reliable: It does not melt at high temperatures, effectively preventing burns.

3、Comfortable and Eco-Friendly: It has excellent moisture absorption and sweat wicking properties. Lyocell enhances softness and ensures environmental friendliness.

Future Optimization

The structure can be adjusted according to occupational needs (e.g., 2:1 rib for firefighters, triple tuck for race car drivers). Alternatively, spinning processes can be optimized to reduce yarn hairiness and improve wear resistance, helping functional textile materials balance "safety, comfort, and cost".

(Note: Data is sourced from the paper Quality of Fine Yarns from Modacrylic/Polyacrylate/Lyocell Blends... (Document No.: materials-16-04386.pdf) and has been originally rephrased.)