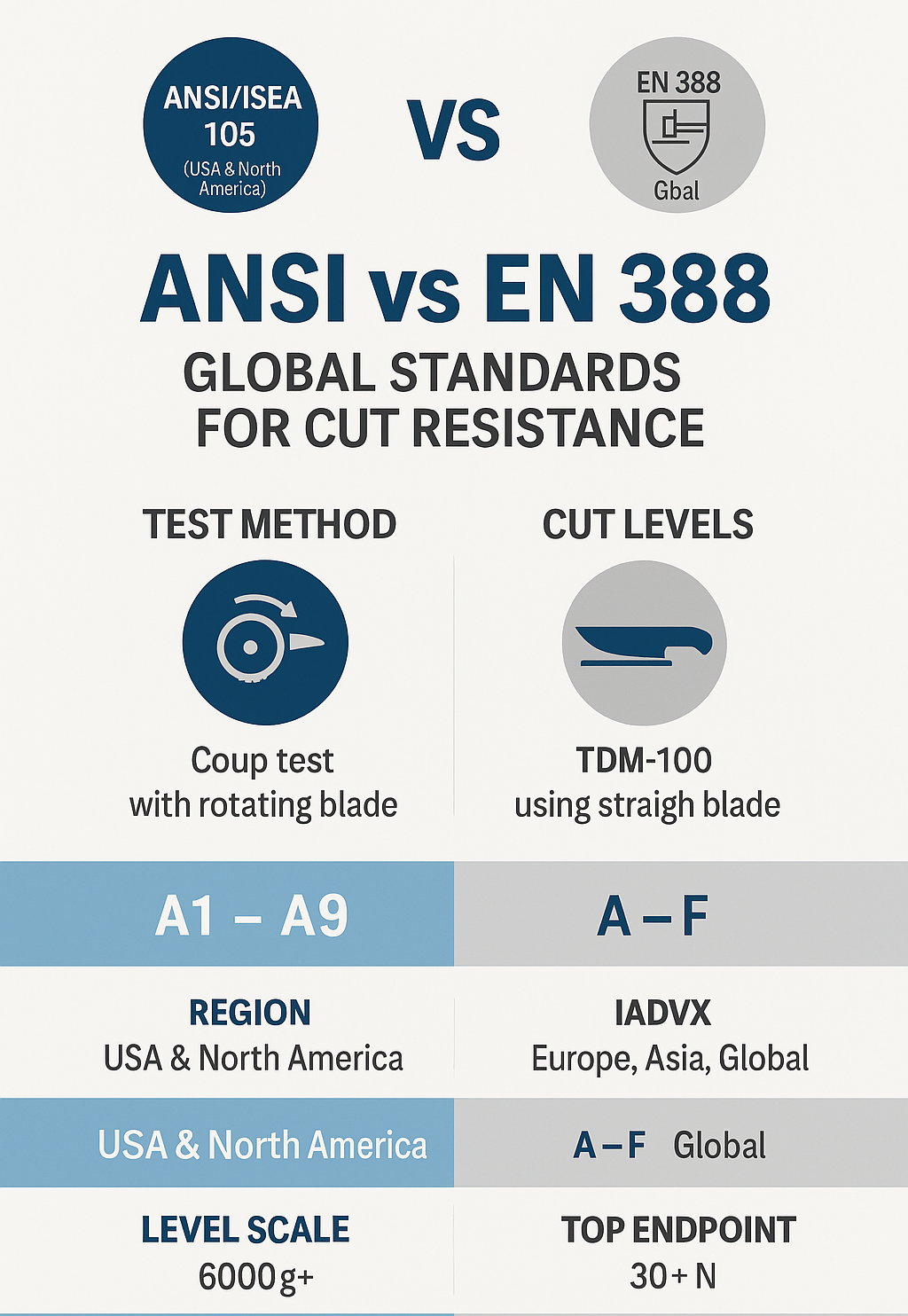

ANSI vs EN388: Understanding the Global Standards for Cut Resistance

When it comes to hand protection, not all standards speak the same language. Two of the most recognized testing systems for cut-resistant gloves and materials are:

ANSI/ISEA 105 (primarily used in the United States)

EN 388 (European Union standard, adopted globally in many countries)

While both aim to evaluate the performance of protective gloves, their methodologies and classification systems differ—sometimes dramatically.

1. Test Methodology

ANSI/ISEA 105 (Cut Resistance):

Uses the TDM-100 testing machine.

Measures the grams of force required to cut through the material with a straight blade.

Cut levels range from A1 to A9, with A9 = highest protection (6000+ grams).

EN388 (Cut Resistance):

Originally used the Coup Test with a rotating circular blade.

Since 2016, added the ISO 13997 test (TDM-based), especially when dulling of the blade occurs.

Cut levels range from A to F, with F = highest protection.

2. Comparison Chart

|

Feature |

ANSI/ISEA 105 |

EN 388 |

|

Main Region |

USA & North America |

EU, Asia, global |

|

Test Type |

TDM-100 (ISO 13997) |

Coup test + ISO 13997 |

|

Cut Levels |

A1 – A9 |

A – F |

|

Units of Measurement |

Grams of force |

Newtons |

|

Higher Number = Safer? |

Yes |

Yes |

3. Practical Implications

Why does this matter for users and distributors?

A glove rated A6 in ANSI may not always be the same as a glove rated E in EN388, even if the cut resistance looks similar.

Compliance & certification varies by market — e.g., EU buyers need EN388, US buyers prefer ANSI.

Choosing the wrong rating may lead to insufficient protection in high-risk applications such as glass handling or sheet metal work.

4. For International Buyers

If you're sourcing gloves or fabrics from China, always confirm:

Which standard the product complies with.

Whether the test method is ISO 13997 (preferred globally).

If you need a dual-certified glove (ANSI + EN388) for wider acceptance.

Conclusion

Both ANSI and EN388 offer essential insights into product performance—but knowing their differences ensures better safety decisions.

At Mingda Protection Textile, we provide globally compliant solutions, tailored to your industry’s demands. From ANSI A9 to EN388 F-rated fabrics and gloves, we’ve got you covered.

Safety isn’t just a feature—it’s a science.